Standard containers are also known as general purpose containers. They are closed containers, i.e. they are closed on all sides. A distinction may be drawn between the following types of standard container:

Standard containers with doors at one or both end(s)

Standard containers with doors at one or both end(s) and doors over the entire length of one or both sides

Standard containers with doors at one or both end(s) and doors on one or both sides

In addition, the various types of standard container also differ in dimensions and weight, resulting in a wide range of standard containers.

Standard containers are mainly used as 20′ and 40′ containers. Containers with smaller dimensions are very seldom used. Indeed, the trend is towards even longer dimensions, e.g. 45′. The principal components of a standard container are shown in following diagram of a 20′ plywood container:

Frame and bottom cross members are made of steel profiles, while three different materials are used for the walls:

1. Steel sheet, corrugated

Characteristics:

low material costs

easy to repair

high tare weight

susceptible to corrosion

difficult to clean owing to corrugated walls

2. Aluminum sheet in conjunction with stiffening profiles

Characteristics:

low tare weight

high material costs

easily deformed, very quickly dented

3. Plywood with glass fiber-reinforced plastic coating (plywood + GRP)

Characteristics:

easy to clean owing to smooth surfaces

easy to repair

strong and resilient, does not dent

moderate material costs

moderate tare weight

The cost advantages have led to the predominant use of steel for container walls.

The floor is generally made of wood, usually planking or plywood. Although wood is relatively expensive, it has substantial advantages over other materials: it is strong and resilient, does not dent, may be easily replaced during repairs and, when appropriately finished, has an adequate coefficient of friction, which is important for cargo securing.

Standard containers may additionally be equipped with certain optional extras:

Forklift pockets: these allow handling of empty containers with forklift trucks. Packed containers must not be picked up in this way unless specifically permitted. Forklift pockets are installed only in 20′ containers and are arranged parallel to the center of the container in the bottom side rails. 40′ containers do not have forklift pockets, since the pockets are relatively close together and such large containers would be difficult to balance. In addition, the forklift truck travel paths are often not wide enough.

Gooseneck tunnel: Many 40′ containers have a recess in the floor at the front end which serves to center the containers on so-called gooseneck chassis. These recesses allow the containers to lie lower and therefore to be of taller construction.

Grappler pockets: In general, containers are handled by top spreaders using the corner fittings or corner castings. However, some containers have grappler pockets for handling by means of grapplers.

Special fittings are available for transporting special cargoes:

Clothes rails for hanging garments: Special lashing rings attached to the top side rail serve to accommodate clothes rails on which textiles may be transported hanging on clothes-hangers. These are often used in the East Asia import trade. Additional lashing rings are installed on the bottom side rail and the corner posts.

Inlet (bulk bag or liquid bulk bag): Plastic liners may be suspended in standard containers for transporting bulk cargo or nonhazardous liquids.

The wooden components of most containers are impregnated against insect infestation, since, when lumber is used, it may, under certain circumstances, be necessary to comply with the quarantine regulations of the country of destination and a phytosanitary certificate may have to be enclosed with the shipping documents. Information may be obtained from the phytosanitary authorities of the countries concerned.

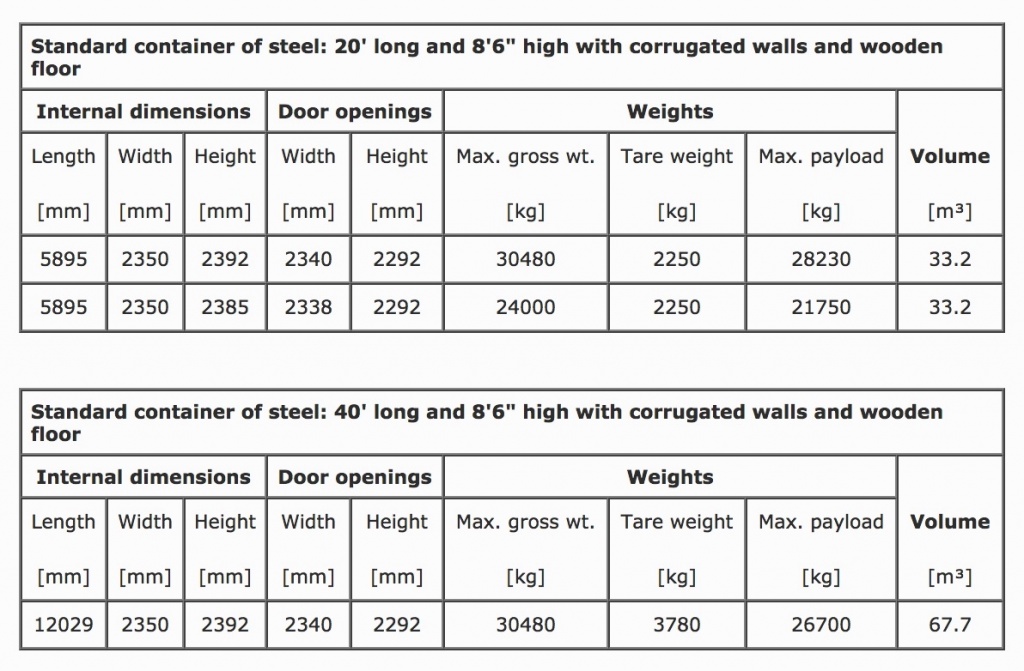

Dimensions/weights

The following are some of the most important details relating to standard container types. The data was taken from Hapag-Lloyd, Hamburg [68].